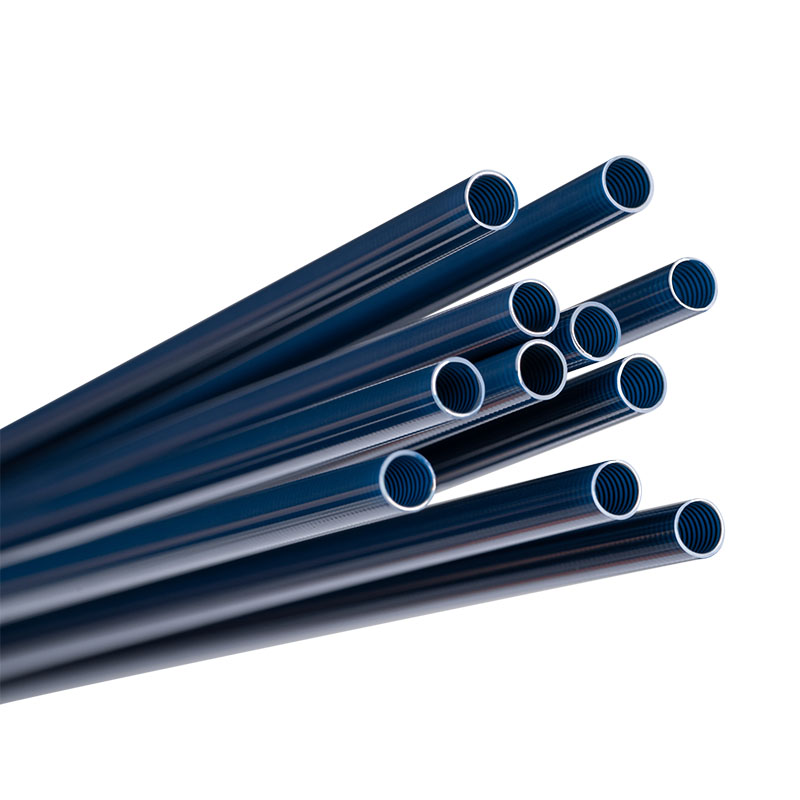

Braided Reinforced Tubing Shaft for Medical Catheter

High-dimensional accuracy

High rotational torque properties

High inner and outer diameter concentricity

Strong bonding strength between layers

High compressive collapse strength

Multi-durometer tubes

Self-made inner and outer layers with short lead time and stable manufacturing

Braid-reinforced tubing applications:

● Percutaneous coronary tubing.

● Balloon catheter tubing.

● Ablation devices tubing.

● Aortic valve delivery system.

● EP mapping catheters.

● Deflectable catheters.

● Microcatheter Neurovascular.

● Ureteral access tubing.

● Tubing OD from 1.5F to 26F.

● Wall thickness down to 0.13mm / 0.005".

● Braid density 25~125 PPI with continuously adjustable PPI.

● Braid wire flat and round with material Nitinol, Stainless steel and Fiber.

● Wire diameter from 0.01mm / 0.0005" to 0.25mm / 0.010", single wire and multi strands.

● Extruded and coated liners with material PTFE, FEP, PEBAX, TPU, PA and PE.

● Maker band ring and dot with material Pt/Ir, gold platting and radiopaque polymers.

● Outer jacket material PEBAX, Nylon, TPU, PET including blending development, color masterbatch, lubricity and photothermal stabilizer.

● Longitude supporting wires and pull wire design.

● Barding patterns one over one, one over two, two over two, 16 carriers and 32 carriers.

● Secondary Operation including tip forming, bonding, tapering, curving, drilling and flanging.

● ISO13485 quality management system.

● 10,000 class clean room.

● Equipped with advanced equipment to ensure that product quality meets the requirements for medical device applications.