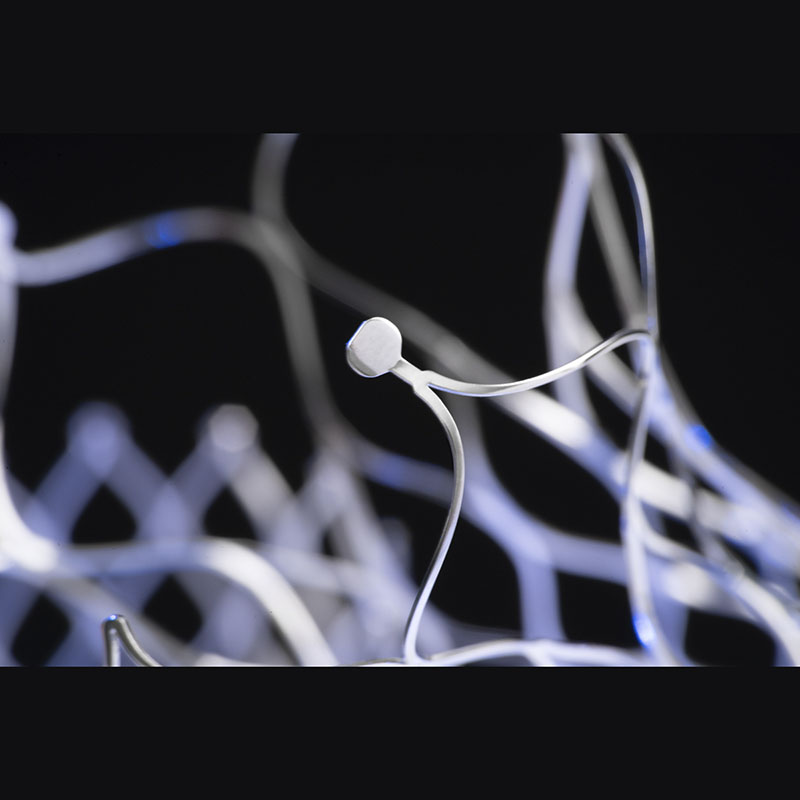

Metal medical components with nitinol stents & detachable coils delivery system

Rapid Response Prototyping

Laser Technology

Surface Finishing Technology

Parylene & PTFE Coating Technology

Centerless Profile Grinding

Heat Shrinking

Microassembly

Test Lab Services

● Coronary and neuro stents.

● Heart valve frames.

● Peripheral arterial stents.

● Endovascular aneurysm components.

● Delivery system and catheter component&.

● Gastroenterology stents.

Stents & Nitinol Components

| Material | Nitinol/ Stainless steel/ Co-Cr /… |

| Dimension | Strut width accuracy: ±0.003mm |

| Heat Treatment | Black/blue/light blue oxide treatment for nitinol components Vacuum treatment for stainless steel & Co-Cr stents |

| Surface Finishing | ● Microblasting /chemical etching and polishing/ Mechanical polishing ● Both internal surface and external surface can be electropolished |

Delivery system

| Material | Nitinol/ Stainless steel |

| Laser Cutting | Femtosecond OD≥0.2mm |

| Grinding | Multi-tapered grinds, long taper grinds for tubing and wires |

| Welding | Laser welding/Soldering/Plasma welding Various combination of wires/tubing/coils |

| Coatings | PTFE/Parylene |

Laser welding

● Automated laser welding for medical devices and components, the minimum diameter of the smallest spot can reach up to 0.0030".

● Welding of dissimilar metals.

Laser cutting

● Contactless processing, minimum cutting slit width: 0.001".

● Processing of irregular structures, repetition accuracy can reach up to ±0.0001".

Heat treatment

● Precise heat-treatment temperature and shape control ensure the phase transition temperature required by the product, thereby meeting the functional requirements of nickel-titanium implantable medical devices.

Electrochemical polishing

● Contactless polishing.

● Roughness of internal and external surfaces: Ra≤0.05μm, superior over the industry average by 0.2μm.

● ISO13485 quality management system.

● Equipped with advanced equipment to ensure that product quality meets the requirements for medical device applications.