Company and factory pictures

PET heat shrink tubing is widely used in medical devices such as vascular intervention, structural heart disease, tumors, electrophysiology, digestion, respiration, and urology due to its excellent properties in the areas of insulation, protection, stiffness, sealing, fixation, and strain relief.

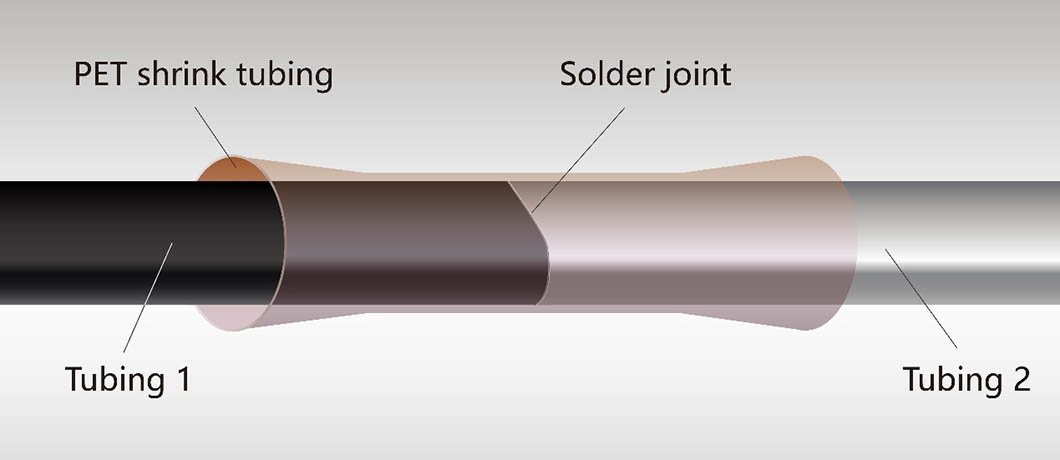

PET heat shrink tubing could tightly wrap irregular-shaped or variable-diameter products

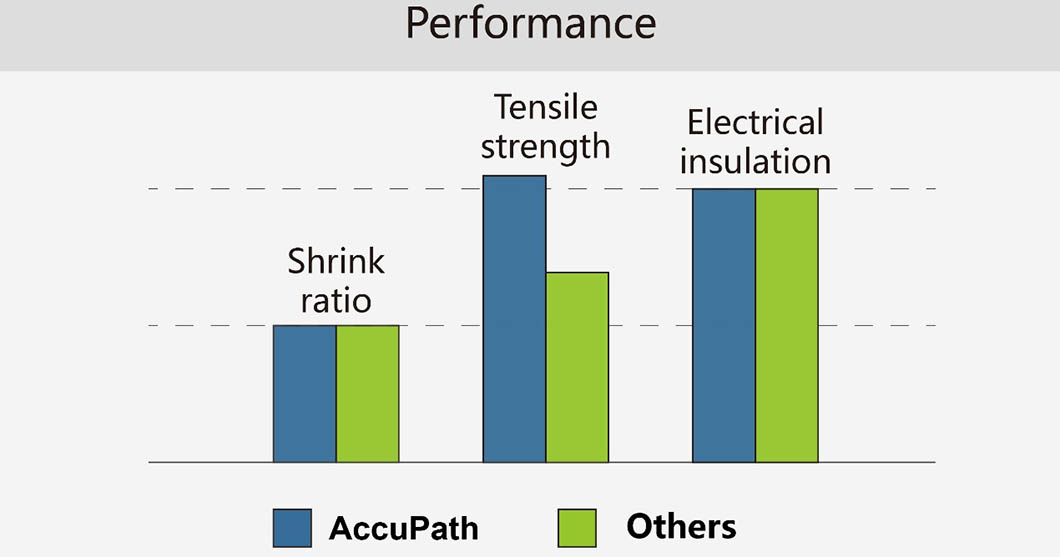

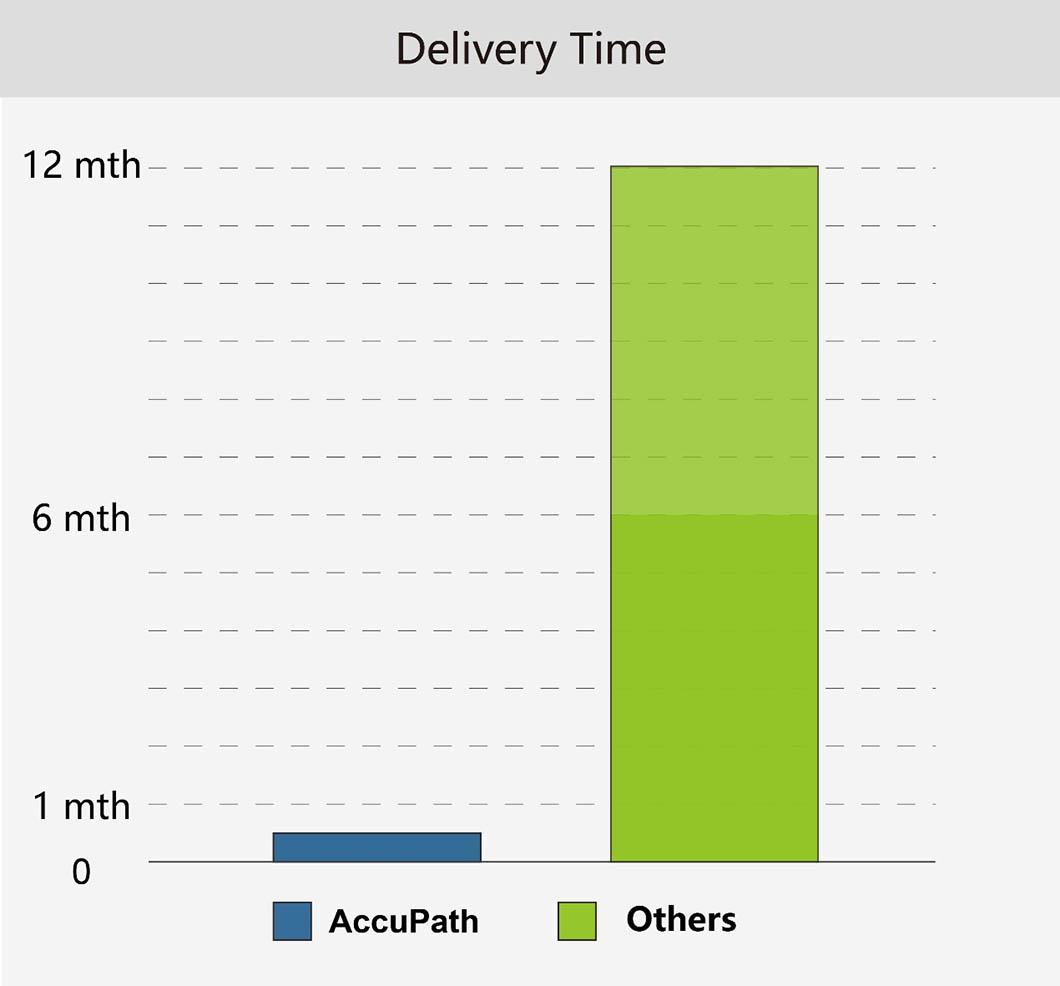

PET heat shrink tubing is developed by AccuPath® to have an ultra-thin wall (the thinnest wall thickness can reach 0.0002'') and high heat shrink ratio (reach up to 2:1), making it an ideal polymer material for design of medical devices and manufacturing technology. This tubing features excellent electrical insulation performance to improve the electrical safety performance of medical devices. Fast delivery is available to shorten the research and development cycle of medical devices.

| ● Ultrathin wall, super tensile ● Lower shrinkage temperature ● Smooth inner and outer surfaces |

● High radial shrinkage ● Excellent biocompatibility ● Excellent dielectric strength |

Product Advantages

Precise tolerance is a must to ensure that extended dimensions consistently meet critical requirements. Experimental tests show that under the same wall thickness, all characteristics of the product can reach or exceed international standards. This is the preferred raw material for high-end medical device manufacturing.

AccuPath®'s PET heat shrink tubing with fast delivery time to meet R&D phase requirements. Standard products can be delivered within 2 weeks, and regular size customization can be delivered within 4 weeks.

Standard size lead time: 2 weeks

Customized size lead time: 4 weeks

| Technical Data | |

| Inner Diameter | 0.25~8.5mm(0.010''~0.335'') |

| Wall Thickness | 0.005~0.200mm(0.0002''-0.008'') |

| Length | ≤2100mm |

| Color | Clear, Black, White and Customized |

| Shrink Ratio | 1.2:1, 1.5:1, 2:1 |

| Shrink Temperature | 90℃~240℃(194℉~464℉) |

| Melting Point | 247±2℃(476.6±3.6℉) |

| Tensile Strength | ≥30000PSI |

| Others | |

| Biocompatibility | Meets ISO 10993 and USP Class VI requirements |

| Sterilization Method | Ethylene oxide, gamma rays, electron beam |

| Environmental Protection | RoHS Compliant |

Quality Assurance

● ISO13485 quality management system.

● 10,000 class clean room.

● Equipped with advanced equipment to ensure that product quality meets the requirements for medical device applications.

Post time: Jun-19-2023