AccuPath® annually provides millions of meters of transparent flexible PO heat shrink tubing to leading medical device manufacturers. Through advanced manufacturing processes and lean production management, it has successfully helped customers reduce material costs by 20-30%. In the meantime, AccuPath®'s unwavering commitment to stable quality and prompt delivery acts as an unwavering driving force for domestic customers involved in the research and production of coronary vascular intervention devices. This enables them to possess unique technological advantages and promotes the development of domestic medical devices.

Addressing Pain Points, Confronting Challenges

In China's medical device industry, the field of coronary vascular intervention has emerged as a pioneer in the adoption of centralized procurement, which has become a longstanding and standardized practice. Consequently, medical device manufacturers are facing a pressing need to explore domestic alternatives with superior cost-effectiveness as substitutes for costly imported raw materials. This strategic shift aims to mitigate any potential disruptions to the production and delivery processes, ensuring seamless operations and enhanced efficiency.

In the realm of coronary vascular intervention, Company A, a leading entity, serves as an illustrative example. Initially, they chose a renowned international brand's PO heat shrink tubing for the assembly and welding of their delivery system. However, in 2022, delays in the delivery of the tubing posed a substantial risk of halting production altogether. Moreover, the cost pressures associated with centralized procurement necessitated the development of alternative materials that could match the same level of quality, while offering faster lead times and reduced costs. Addressing this critical situation, AccuPath® promptly developed a range of PO heat shrink tubing options for the client. These alternatives exhibited performance on par with competitors, with lead times compressed to 1-2 months, resulting in a remarkable 20% cost reduction for the PO heat shrink tubing.

AccuPath's Heat Shrink Tubing

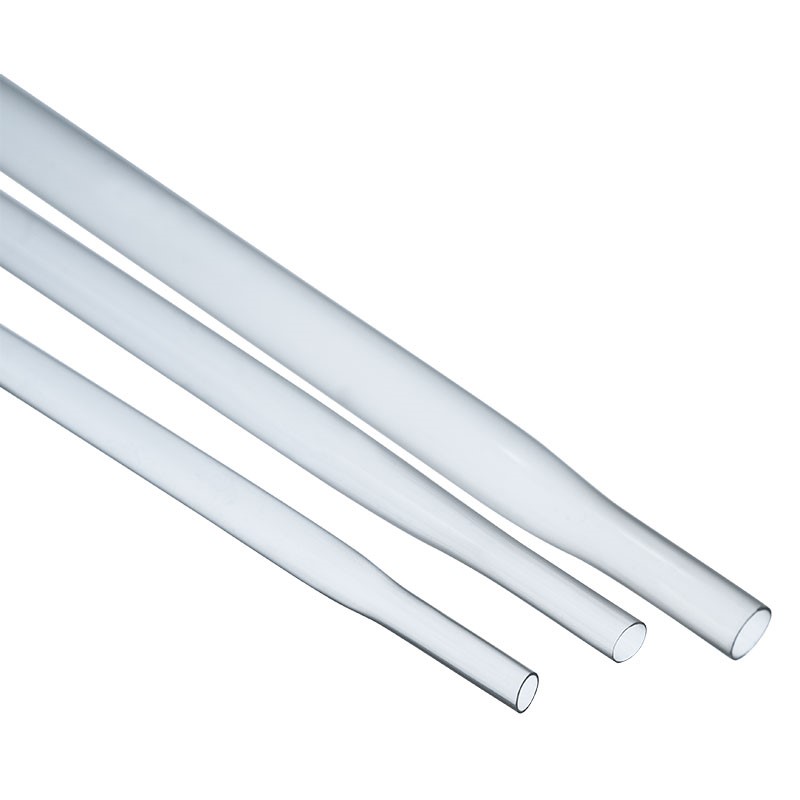

According to specific application requirements, AccuPath® recommends the use of Transparent Flexible PO Heat Shrink Tubing. This PO heat shrink tubing is made from imported resin and undergoes multiple manufacturing processes, offering performance comparable to the imported heat shrink tubing previously used by customers. It provides auxiliary processes and device protection for the welding production of balloons and stent delivery systems.

The performance advantages of AccuPath® Transparent Flexible PO Heat Shrink Tubing for customers include:

● High transparency

● Shrink ratios of 2:1, 3:1, or 4:1

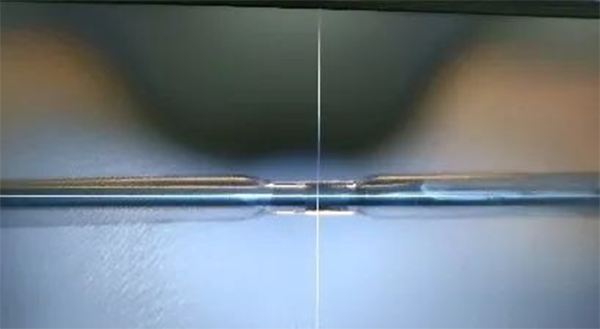

● Withstands laser energy of over 1300mW, does not melt or emit significant smoke at high temperatures

● Leaves no filamentary residue on the protected product surface after removal upon completion of product welding

● Features good tearability in images, suitable for easy removal by hand or automated equipment.

Furthermore, AccuPath® provides the flexibility to supply customers with PO heat shrink tubing featuring a range of finished inner diameters, fully recovered inner diameters, and fully recovered wall thicknesses. Customization options for sizes and colors are also available to accommodate specific requirements.

AccuPath® Core Advantages: Empowering Customers with Multiple Value-added Benefits

AccuPath®'s PO heat shrink tubing brings a multitude of advantages to customers in the production of balloon and stent delivery systems:

Quick Responsiveness: AccuPath® prioritizes shorter delivery times, enabling prompt responses and ensuring the smooth execution of customers' production plans.

Quality Assurance: Achieving a yield rate of over 99% and eliminating the need for rework or repair, AccuPath® reduces production delays and additional costs associated with quality issues. Rigorous control measures at every step of the production process guarantee products that meet stringent quality standards.

Cost Efficiency: By helping customers reduce heat shrink tubing procurement costs by 20 to 30%, AccuPath® effectively addresses the challenge of inflated material prices, resulting in improved economic benefits.

When asked about the collaboration with AccuPath®, the client expressed, "AccuPath® holds a leading position in the market for implantable medical device materials and has been one of our primary suppliers. This collaboration has not only helped us address the challenges of high material premiums and long delivery cycles but also provided us with valuable technical support for their high-performance PO heat shrink tubing. It has helped us enhance the product quality of our coronary artery intervention delivery systems, accelerate time-to-market, and ensure supply chain stability.

In addition to coronary artery intervention delivery systems, AccuPath®'s dedicated and efficient heat shrink tubing R&D team, leveraging its incomparable localization advantages and core technologies in the field of implantable medical device materials, offers effective solutions for medical devices in diverse domains, including structural heart disease, oncology, electrophysiology, digestive health, respiratory care, and urology.

Post time: Oct-18-2023