Abstract

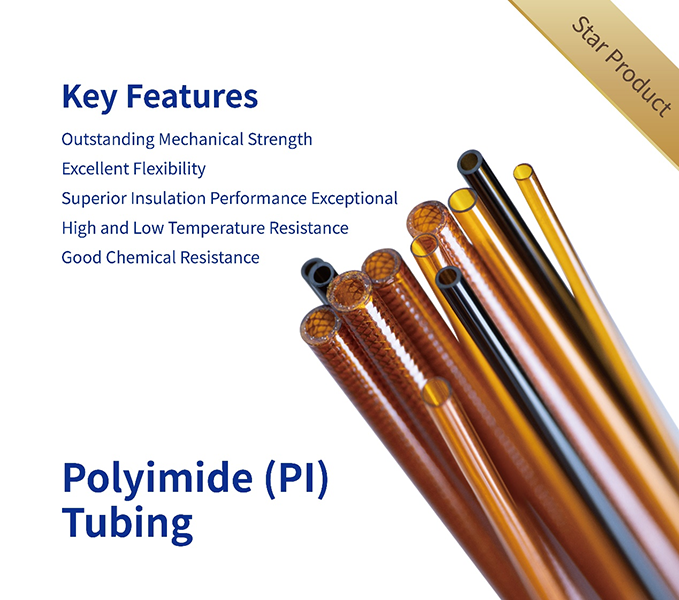

The innovation of high-end medical devices is inseparable from the support of high-performance materials. Polyimide (PI) is increasingly becoming ideal for minimally invasive interventional medical devices due to its excellent mechanical strength, flexibility, insulation, resistance to high and low temperatures, chemical resistance, and biocompatibility. AccuPath®, through years of independent research and exploration, has developed key manufacturing technologies surrounding PI tubing, such as size precision, strength and toughness, lubrication, and braided composite, making its main technologies and products reach the leading level in China and the advanced level internationally.

Main Text

Full Technology, Wide Applications

AccuPath® possesses comprehensive PI tubing technology, which can be widely used in various minimally invasive interventional medical devices such as balloon catheters, electrophysiological catheters, imaging catheters, and stone retrieval baskets.

Through a blending process, it offers various color solutions.

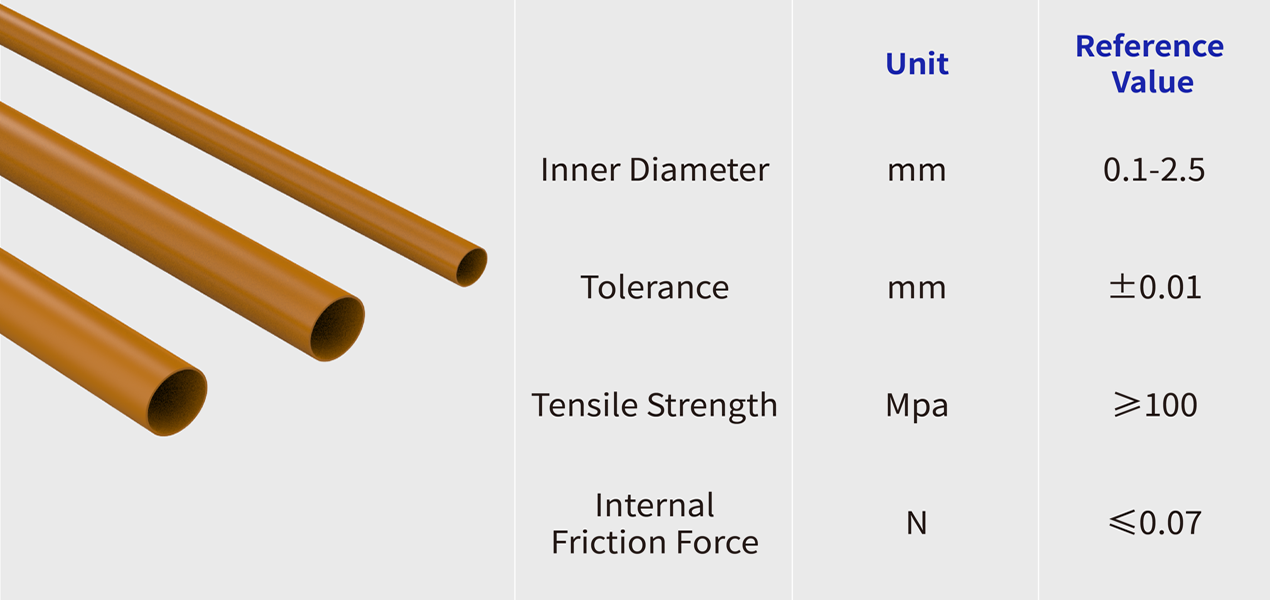

Lubrication modification can reduce the friction coefficient by up to 25%, meeting the technical requirements of inner and outer surface lubrication and thin walls.

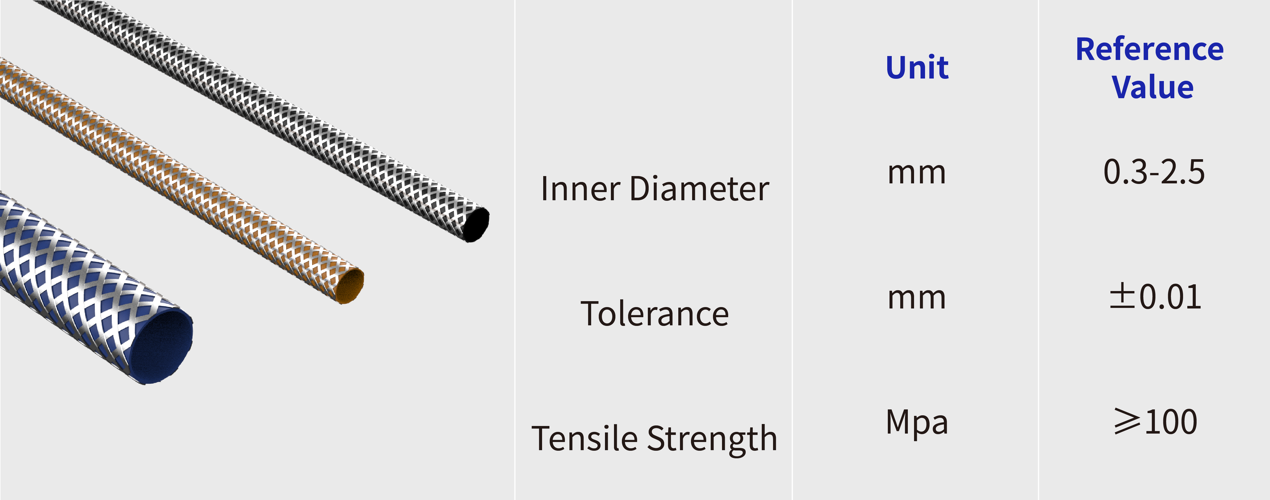

Through braided composite reinforcement technology, it meets the technical requirements of high tensile strength and high burst pressure resistance.

With an inner layer of PTFE and an outer layer of PI, it meets the technical requirements of a high-lubrication inner cavity and thin walls.

By combining the strengths of PEBAX and PI, a synergistic effect is produced, further enhancing comprehensive performance and providing a better material choice for the research and innovation of high-performance medical devices.

By combining the strengths of TPU and PI, a synergistic effect is produced, making the PI/TPU tube have superior comprehensive performance, providing a richer material choice for the research and innovation of high-performance medical devices.

By combining the strengths of PA12 and PI, a synergistic effect is produced, making the PI/PA12 tube have superior comprehensive performance, providing a better material choice for the research and innovation of high-performance medical devices.

International Advanced, Domestic Leading

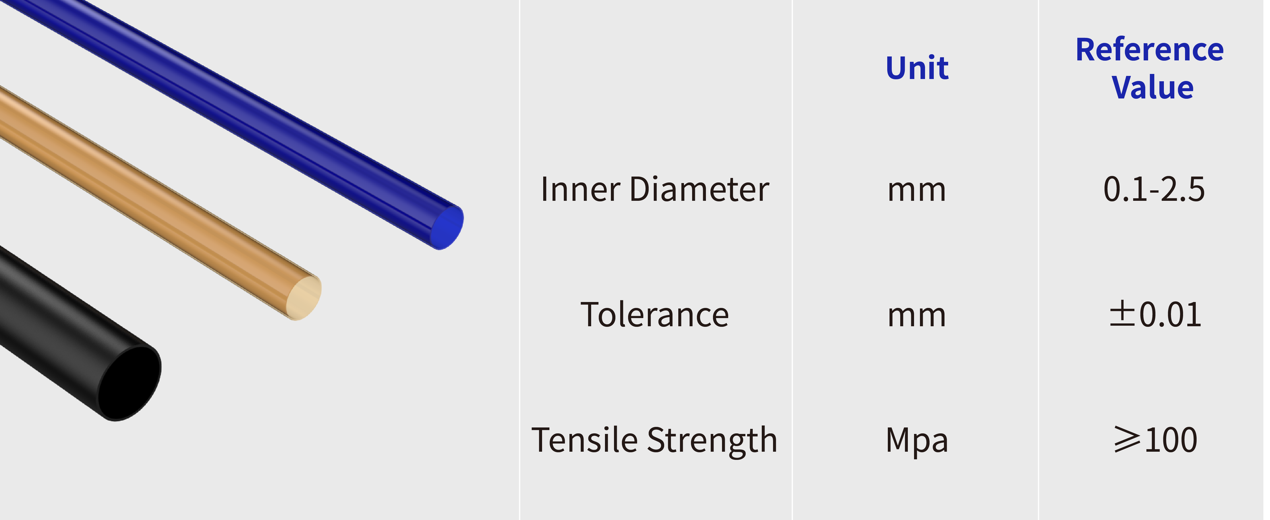

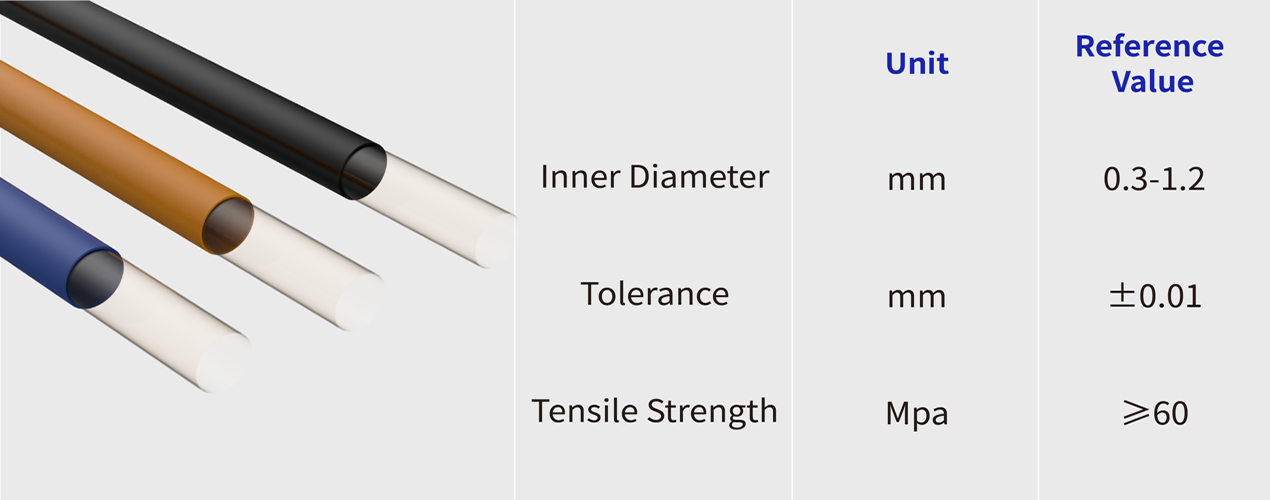

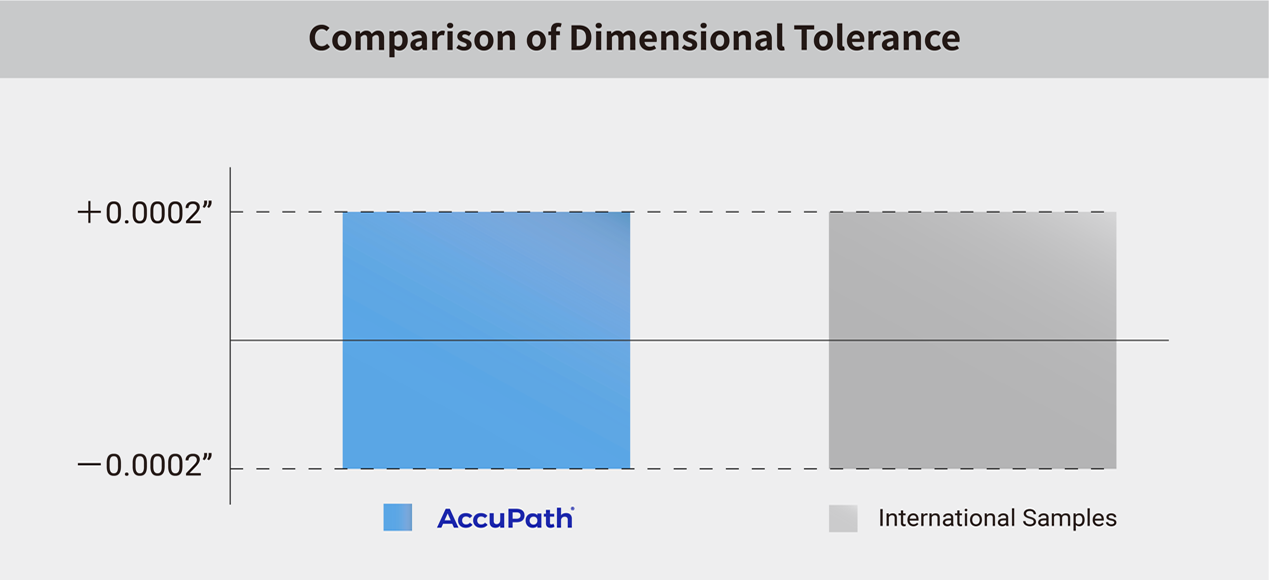

- Small Dimensional Tolerance

High precision in size enhances the push performance of interventional medical catheters, reducing the difficulty of surgical operations for doctors.

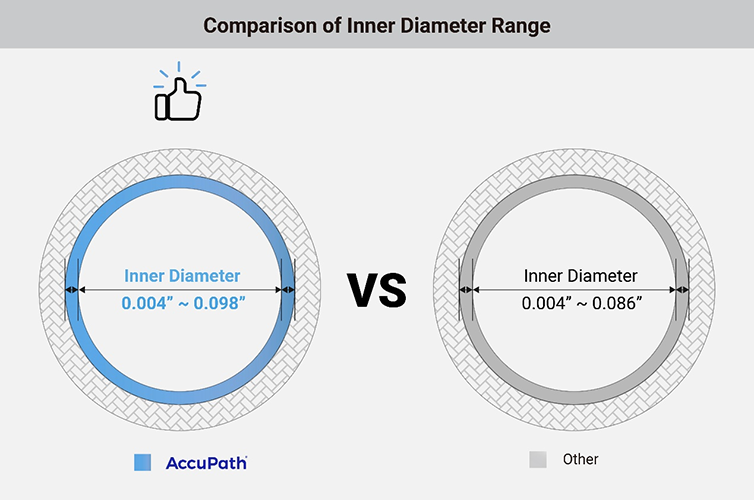

- Wide Range of Inner Diameter Specifications

A wider range of inner diameter specifications provides more PI tube solutions for the research and innovation of high-performance medical devices, expanding the application range of PI tubes.

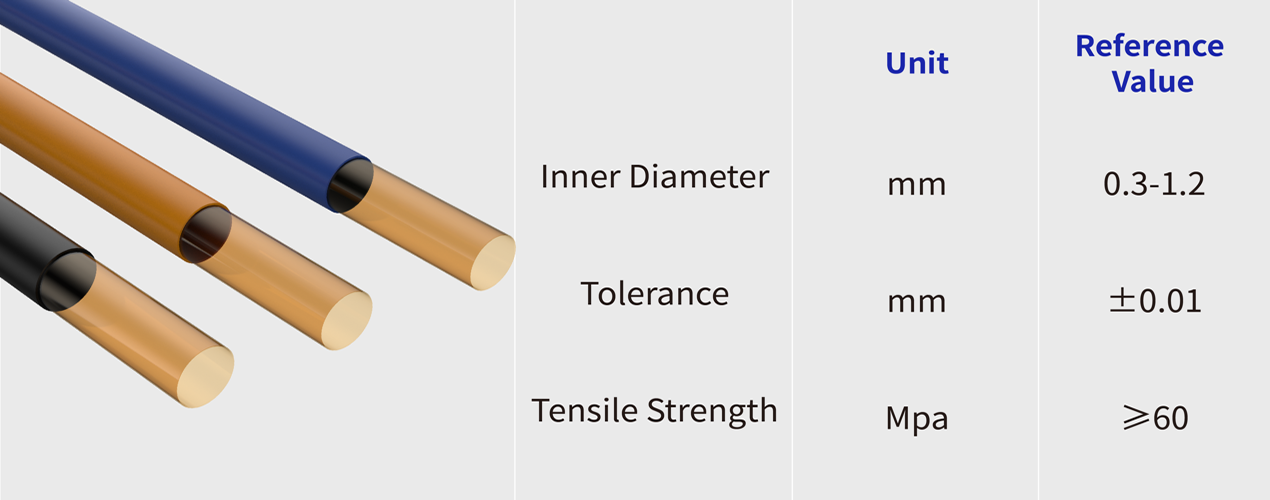

- High Tensile Strength

Excellent tensile strength improves the mechanical strength of interventional medical catheters, making the tubing less prone to breakage or deformation, and reducing the risk of surgical operation for doctors.

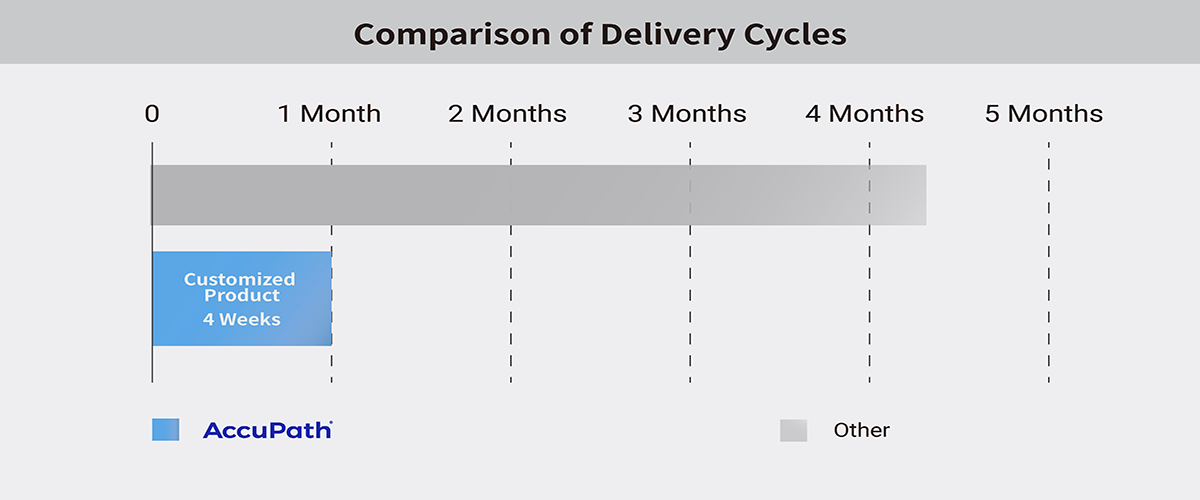

Outstanding Supply Chain

AccuPath® promises to provide industry-leading rapid delivery services. For conventional specification products, the company can provide samples within 3 days (and 2 weeks for customized specification products), and the fastest delivery time for formal orders can be shortened to 4 weeks, ensuring that customers can receive high-quality products on time.

Conclusion

Every technological innovation will bring better treatment options to patients. The innovation of AccuPath®’s Polyimide (PI) tubes marks the progress of materials science and brings breakthrough progress to minimally invasive interventional medical surgery. In the future, we will continue to work towards making safer and more effective medical technology accessible to every patient.

Post time: Jun-24-2024