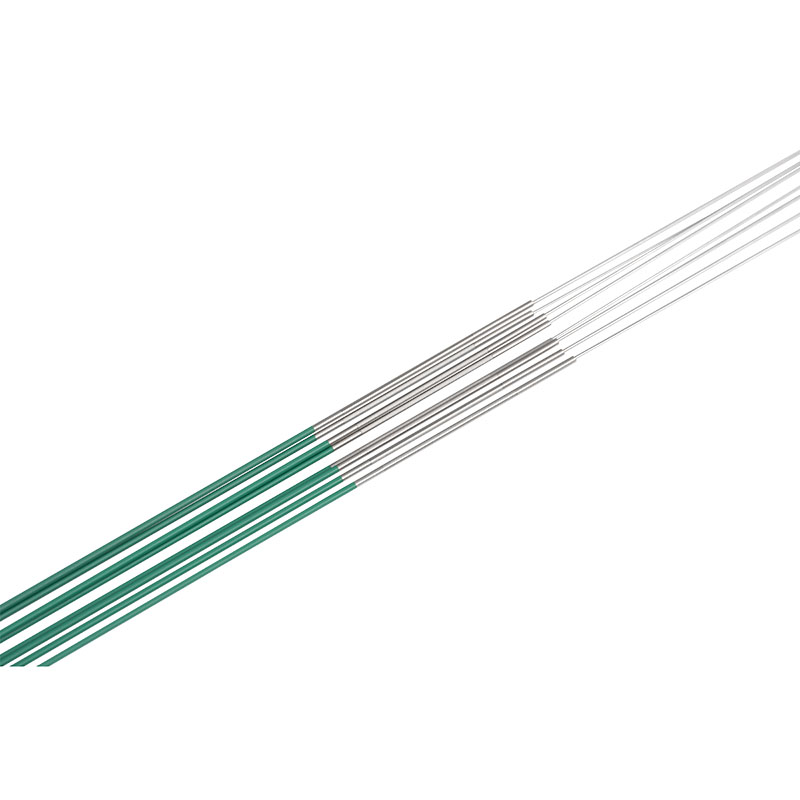

PTFE Coated Hypotube with Comprehensive Processing Capability

Safety (Comply with ISO10993 biocompatibility requirements, comply with the EU ROHS directive, and comply with the US USP Class VII standard)

Pushability, Traceability and kink (Excellent performance of metal pipes and wires)

Smoothly (Customize the friction coefficient according to customer needs)

Stable supply chain: With full process independent research and development, design, and production processing technology, short delivery time, customizable

Independent injection molding platform: It has a special Luer taper design, development and injection molding platform, which can provide customized design and customization according to different designs and needs of customers

CNAS accredited testing center: With testing capabilities such as physical and mechanical performance testing, chemical performance testing, microbiological testing, material analysis testing, etc., it can quickly respond to customer needs

PTFE coated hypotube is used for a wide range of medical device applications and as a manufacturing aid, including:

● PCI treatment surgery.

● Sinus surgery.

● neurointerventional surgery.

● Peripheral Interventional Surgery.

| Unit | Typical Value | |

| Technical Data | ||

| Material | / | 304 SS, Nitinol |

| OD. | mm (inch) | 0.3~1.20mm (0.0118-0.0472in) |

| Tube wall thickness | mm (inch) | 0.05~0.18mm |

| Dimensional tolerance | mm | ±0.006mm |

| Color | / | Black, Blue, Green, Yellow, purple,ect. |

| Coated thickness (one side) |

Mm (inch) |

4~10um (0.00016~0.0004in) |

| Others | ||

| Biocompatibility | Meets ISO 10993 and USP Class VI requirements | |

| Environmental Protection | RoHS Compliant | |

| Safety (Reach Test) |

Pass | |

| Safety | PFAS Free | |

● ISO13485 quality management system.

● 10,000 class clean room.

Write your message here and send it to us